| Max Feed: 158 GPH (600 LPH) |

| Max Pressure: 125 PSI (8.6 bar) |

Description

Flex-Pro A4 Series Peristaltic Pump for high pressure and high accuracy applications.

- Feed Rates to 158.5 GPH

- Pressures to 125 PSI

- 4-20mA (A4V only), Pulse Input (A4V only) and Manual Speed Control

- 2500:1 Turndown ratio

- Patented Tube Failure Detection

- Brushless DC Motor

- NEMA 4X (IP 66) Washdown

- 2 Year Warranty

Features

- Benefits of a Peristaltic Pump:

- Peristaltic pump design does not have valves that can clog requiring maintenance.

- Self priming – even against maximum line pressure. By-pass valves are not required.

- Cannot vapor lock or lose prime.

Capabilities:

- 2500:1 turndown ratio.

- Output rates to: 158.5 GPH (600 LPH) and pressures to 125 PSI (8.6 Bar).

- Inject at maximum pressure in either direction (clockwise and counter clockwise).

Communication & Interface:

- SCADA Inputs include: 4-20mA, 0-10Vdc, and Pulse inputs for remote external

speed control and 0-30 VDC / contact closure remote start/stop. - Operator friendly digital touch pad with menu driven software.

- VGA Graphic multi-color backlit LCD displays remote/local control status, motor speed,

output rate, input signal values, service and alarm status. - Outputs include: Scalable 4-20mA or pulse, one 250V/6A relay and three 115V/1A contact closures

assignable to monitor up to 17 different pump functions including TFD, FVS, remote/local

control setting, motor on, fault, current operating mode, and others. - Compatible with Blue-White’s output Flow Verification Sensor (FVS) system.

Superior Engineered Design:

- Two CNC precision machined squeeze rollers and two alignment rollers for optimum squeeze,

unparalleled accuracy, and tube life. - Heavy duty rotor – single piece plastic rotor means no flexing and increased accuracy with

no metal springs or hinges to corrode. - No maintenance brushless variable speed motor.

- Specially engineered tubing for long life at high pressures. Meets FDA 21 CFR requirements

for food contact applications.

Patented Features:

- Patented Tube Failure Detection (TFD) system. Senses tube failure by detecting

chemical in the pump head. No false triggering. - Patented Component Control System. A method used to control two or more positive displacement pumps in a system.

- Patented feature to extended tube life.

- Patented Safety Switch. Ensures safety of operator during regular pump head maintenance.

Specifications

| Max. Working Pressure: | 125 psig (8.6 bar) Note: see individual pump tube assembly maximum pressure ratings. |

| Max. Fluid Temperature: | 3/8” OD x 1/4” ID tubing connections: 130°F (54°C) M/NPT connections: 185°F (85°C) Note: see individual pump tube assembly maximum temperature ratings. |

| Ambient Operating Temperature: | 14°F to 115°F (-10°C to 46°C) |

| Ambient Storage Temperature: | -40°F to 158°F (-40°C to 70°C) |

| Maximum Viscosity: | 12,000 Centipoise |

| Maximum Suction Lift: | 30 ft. Water at sea level (14.7 atm psi) |

| Operating Voltage: | 96 to 264VAC-50/60Hz, 350W |

| Power Cord Options: | 115V60Hz = NEMA 5/15 (USA) 230V60Hz = NEMA 6/15 (USA) 220V50Hz = CEE 7/VII (EU) 240V50Hz = AS 3112 (Australia/New Zealand) |

| Motor: | Brushless DC |

| Motor Speed Adjustment Range 2,500:1: | 0.04% – 100% motor speed |

| Motor Speed Adjustment Resolution: | 0.1% increments > 10% motor speed 0.01% increments > 1% motor speed and < 10% 0.001% increments < 1% motor speed |

| Display: | 3 color VGA backlit LCD, UV resistant |

| Display Resolution: | 0.1 > 10% motor speed 0.01 > 1% motor speed and < 10% 0.001 < 1% motor speed |

| Keypad: | Ten button positive action tactile switch keypad |

| Enclosure: | NEMA 4X (IP66), Polyester powder coated aluminum. |

| Security: | Programmable 4-digit password |

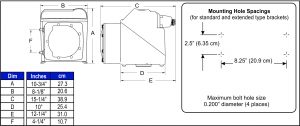

| Maximum Overall Dimensions: | 12-1/8”W x 14-1/4”H x 18-5/8”D (30.8W x 36.1H x 47.3D cm) |

| Approximate shipping wt: | 58 lb. (26.3 Kg) |

Dimensions

Literature

Instruction Manual – A3V & A4V PDF (80000-463)

Instruction Manual – A3F & A4F PDF (80000-419)

Technical Data Sheet (85000-098)

Engineering Spec Sheet (DOC)

Tubing Selection Guide (85000-120)

Product Enquiry