| Pipe Sizes: ½” to 100″ pipe |

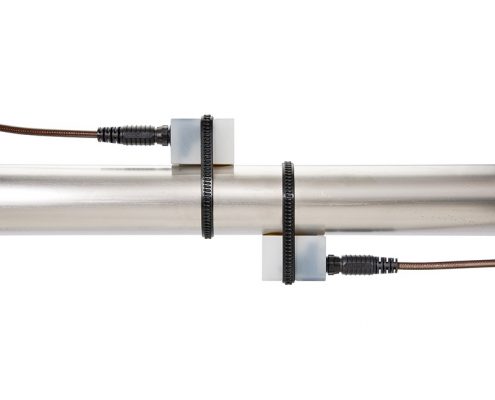

| Mount Method: T-Track |

- User-selectable Doppler or Transit Time operating modes for measurement of both clean and dirty fluids

- The meter can be factory configured for easy installation

- Custom quality metric algorithms and DSP technology for reliable, high accuracy measurements

- To allow for changes in the fluid’s particle count, SonicPro monitors the signal gain and employs an

Automatic Gain Control (AGC) algorithm that periodically adjusts the gain, maintaining the optimum power level - Smart external communication with simple, intuitive, Sonic-Pro software

- Portable, rugged carrying case for easy transportation between applications

- 2 year factory warranty

Pipe Sizes

- T-Track fitting allows for small pipe diameter capabilities (1/2”-24”)

- Pipe size range ½”-100”

Fluid

- Virtually any acoustically conductive fluid, Dirty or Clean

Doppler Mode:

-

- Requires particles to be present in the flow stream to “reflect” the sound waves. (ie. Air bubbles, sand, etc.)

Operational Environment:

-

- fluid contains .02%-15% (200-150,000 ppm) of particles.

Transit Time Mode:

-

- Requires relatively “clean” fluid to enable the sound waves to complete a circuit.

Operational Environment:

-

- 0%-10% (0-100,000 ppm) of particles.

Accuracy

- +/- 1% of rate in Transit-Time mode greater than 1 ft/sec fluid velocity

- +/- 0.01 ft/sec in Transit-Time mode less than 1ft/sec fluid velocity

- +/- 2% of rate in Doppler mode greater than 5 ft/sec fluid velocity

- +/- 0.10 ft/sec in Doppler mode less than 5 ft/sec velocity

INTERFACE & DATA

Data logging:

- to standard SD Card supplied with unit. User configurable to time interval, flow rate and total set-point triggers. 500,000 events with included 32MB SD Card.

Optional Computer Connection:

- Ethernet, USB, RS-232, RS-485. Permits remote access and control of all functions including real-time display, system configuration, data logging, remote data capture as well as process control functions. Software permits remote internet access through local network setup.

Optional Process Control:

-

- Three independently configurable 10 amp, form C relays. Configure to flow rate for high/low/range rate alarm for to flow total for wither manual trigger batch operations of flow triggered batch operations.

-

- 4-20 mA output: Fully configurable

-

- 0 – 1000Hz Pulse Output : Fully configurable

Environment

- NEMA 4X (IP66), Powder Coated aluminum, SS clamps & hardware

Dimensions

Meter size:

- 11” H x 8 ½”W x 5” D (279H x 218W x 127D mm)

Shipping dimensions:

- 21” H x 17” W x 9 ½” H

Weight:

- 24 lb. (10.9 Kg.) Includes carry case, Excludes T-Track fixture

S3: |

High quality 320 x 240 pixel QVGA backlit LCD display. Five button, fully configurable, tactile switch keypad interface. Security: master & configuration passwords. |

S2: |

High quality 320 x 240 pixel QVGA backlit LCD display. Two button interface, allows user access to clear accumulated total & swap rate & total display fonts. Communication package required to access configuration menu. |

S1: |

No local display. Factory configured for one application. Communication package required to access configuration menu and data log. |

For Small Pipe dimensions:

½” to 24″

|

|

-

-

- For more general information, refer to the

-